According to Grand View Research, the global

aerospace component manufacturing market size is expected to expand to USD 1.25 trillion by 2027, at a CAGR of 4.1 per cent by 2027. Some of the major driving factors behind this growth are the rising demand for fuel-efficient and lightweight aircraft, and the growing regulations on reducing greenhouse emissions. Furthermore, increasing passenger and freight traffic in emerging economies is driving the demand for next-generation aircraft, thus boosting the market growth.

Owing to the increased growth of aircraft component manufacturing, China and India are expected to become the leading markets in the near future. Today, collaboration of the major companies entering into a joint venture is also becoming one of the major trends in this segment, which is helping the companies sustain in the highly competitive market in terms of geographical expansion, technological advancements, and lowering the risk of failure.

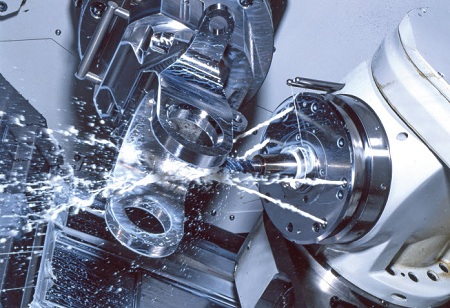

To improve the aircraft performance and cost-efficiency, the market has been witnessing the incorporation of lightweight materials for aerospace parts manufacturing.

For the ability to retain strength at high temperatures with superior corrosion resistance, the players in this segment are looking at lightweight aluminum alloys. The commercial aircraft segment is witnessing the highest demand with improved trade relations across the globe. Besides, the increasing demand for cargo services is also expected to drive the segment growth in the near future.

In terms of product quality and design, the players operating in the aerospace component manufacturing market face competition, wherein, they are targeting customers with customized requests to sustain in the market. While replacing the traditional manufacturing process of smaller aircraft components utilizing complex structures, the major players are expected to adopt emerging technologies such as additive manufacturing.

Insight into Product Manufacturing

According to a recent report, the insulation components segment is expected to witness the fastest CAGR of 6.3 per cent owing to the rapid replacement rate of the products. The rising aircraft MRO activities is another important factor that is expected to fuel the demand for these components. Adding to it, the report also expects cabin interior manufacturing to reach USD 117.4 billion by 2027, due to extensive use of high-strength and lightweight materials.

“In 2021, commercial aerospace manufacturers are likely to focus on restructuring and cost reduction to position themselves for profitable growth in the long term. The industry is also likely to take advantage of the pandemic and its subsequent drop in demand to transform supply chains,” says a Deloitte report.

As avionics manufacturing is designed to increase the safety and utility of an aircraft, it is expected to grow parallel with aircraft manufacturing. While, Actuators are used in all the systems of an aircraft including oxygen, air, hydraulic, fuel, and water systems, it accounts for a major share of avionics manufacturing. Furthermore, actuators are being used in flaps, landing gear, and weapon systems. With time, the industry is going to see an evolution of new technologically advanced replacement of the current components being used or their enhancement.