Thin films are thin layers of materialswhose thicknesses range from fractions of a nanometer to several micrometers. While thin films are commonly used in the industrial world for coatings, they also have other uses, such as converting light energy into electrical power and advanced memory storage devices. For theirversatility, thin films are used in various technological applications.

How Are Thin Films Made?

Polymers, ceramics, and inorganic compounds are the common materials used to create thin films. They can be applied to various surfaces using different deposition techniques, such as evaporation, chemical vapor deposition, and sputtering.

Quality control and client specifications will dictate this intricate creative process. Furthermore, the factors involving cost and efficiency must also be taken into consideration when manufacturing thin films. You can learn more about the thin film deposition process here.

What Are The Common Types Of Thin Films?

Thin films are incredibly versatile, not just in terms of their uses but also in the range of varieties available. From hard titanium to optically clear coatings and everything in between, the following six main kinds of thin films can be used for various purposes.

1. Mechanical Thin Films

Mechanical thin films are unique thin films typically composed of hard, corrosion, and wear-resistant materials. In coating applications, thin mechanical films can be applied to virtually any surface—metals, plastics, glass, and so on—to provide additional strength against friction and abrasion. They also offer superior anticorrosive protection, thus allowing them to be deployed in various industries and applications, such as aerospace engineering and transportation logistics.

2. Optical Thin Films

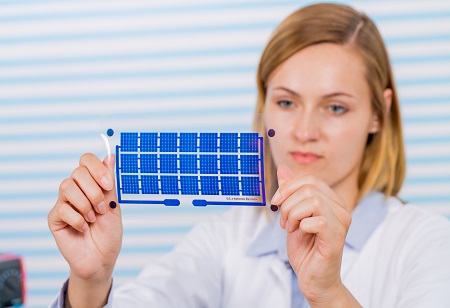

Optical thin films are a coating typically applied to materials to give the desired optical properties. They’re one of the

innovations in the solar energy sector to make flexible, lightweight, and ecologically friendly solar panels.

These specialized coatings can enhance performance, increase reflectivity, or change color, depending on