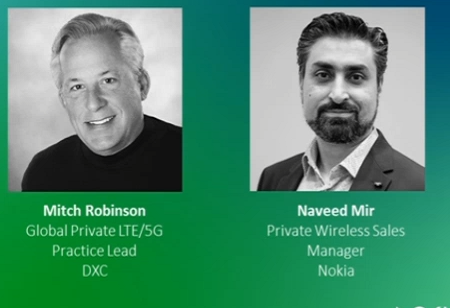

In a webinar hosted by Industry Week, the discussion was focused on applications of industrial-edge technology. The discourse started off with Mitch Robinson, Global Private LTE / 5G Practice Lead, DXC, emphasizing the business need for secure, reliable and high-performance communication solutions. He proceeds to elaborate on the pros of Wi-Fi technology, which is limited by its range, while businesses that are spread over a large area can only be covered by private LTE. Wi-fi signals can be obstructed by buildings, but LTE signals can penetrate numerous buildings. He concludes his address by stating a real use case where technology was leveraged to improve an outdated infrastructure to a state-of-the-art infrastructure complete with means for worker safety with digital worker initiatives. He attributes the success of this digital transformation to the mission-critical industrial edge compute platform.

Naveed Mir, Private Wireless Account Director, Manufacturing & Logistics, Nokia, proceeds to elaborate on the application of the mission-critical edge compute platform by elaborating on numerous use cases across various sectors.

This is explained by Nokia’s partner, Portalify, using the SmartView application. This technology allows workers in an industrial environment, be it indoors or outdoors, to have a critical awareness of any situation. It provides alerts and information about worker safety.

Lack of situational awareness is said to be the biggest contributor to accidents in the manufacturing environment. This technology can allow workers to connect to a control room. In most situations, some workers are in contact with each other by instant communication. But not all workers have access to this. Lone workers who work off-site or in hazardous locations are left out. This technology creates access to the control room where everyone's real-time monitoring is possible. This is also accessible to workers who can also utilize this software on their personal handset.

This is explained with svarmony’s aryve software. This application is optimal for indoor usage. It is based on mixed reality. It utilizes LiDAR data of the complex, which is scanned prior and stored on the local edge server. This allows workers to react to faulty machines somewhere in the complex without relying on visual cues or asking others for directions. Uponn reaching the area which houses the faulty equipment, the handset can use its camera and disburse the appropriate manual or tutorial for carrying out the troubleshooting actions.

It is also useful for new people around the building complex who are unfamiliar with the floor plan and aids in navigation. This has the capability to boost productivity, train new employees, and increase awareness, all from the palm of your hand.

This use case is equivalent to an SOS Signal, which is explained with Nokia’s partner secapp. In case of an unforeseen circumstance, where productivity has to be stopped and a worker needs emergency medical care, which requires the presence of a professional. Help can immediately be called from the handset’s inbuilt features. Data has proven that this technology allows 90% faster response rates compared to securing aid by traditional methods, which involves a lot of time.

This leverages LLM and Generative AI and can be accessed/communicated with a chatbot. When a machine is down due to an error code and productivity is going down, Nokia’s Workmate solution provides them with not just the fix but also the contextual information that it has collected through the faulty machine. The user can communicate with the chatbot by using audio cues to identify the problems they face and, in response, give them instructions for corrective actions.

This feature can also be extended to perform preventive maintenance and allow users to have contextualized data and access to a real-time expert trained specifically for the environment compared to a third-party application, which has a higher probability of being inaccurate.

We use cookies to ensure you get the best experience on our website. Read more...