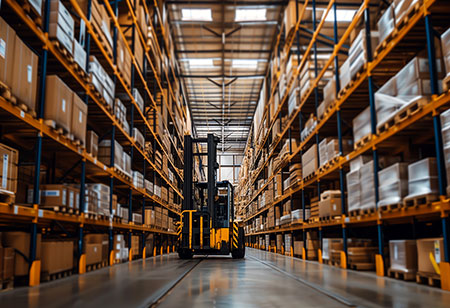

Whether you're running a manufacturing plant, construction site, or ware- house, choosing the right equipment for your bulk material handling needs is crucial. It can impact your efficiency, productivity, and even safety.

However, with so many options available, the selection process can be challenging. In this article, you'll find practical advice and essential consi- derations to help you choose the equipment that best fits your requirements.

Understand Your Material

The first step in selecting the right bulk material handling equipment is understanding the material you'll be handling. Different materials require various handling techniques and equipment. For instance, handling powdery substances like flour differs vastly from dealing with coarse materials like coal or gravel.

Consider the material's characteristics, such as size, abrasiveness, corrosiveness, and moisture content. This knowledge will guide you in choosing equipment that can handle your material without causing damage or inefficiency.

Assess Your Capacity Requirements

Once you've got a good grasp on the type of material you're dealing with, it's time to consider your capacity requirements. How much material do you need to move, and how quickly? Equipment capacity is often measured in tons per hour, and selecting equipment that matches your volume needs ensures you won't end up with bottlenecks in your process.

Moreover, think about future growth—opting for a slightly higher capacity than your current needs can provide room for expansion without necessitating immediate upgrades. In industries like specialized manufacturing, where production demands can fluctuate based on client orders and market trends, choosing adaptable equipment that can scale up or down efficiently is particularly important.

Consider The Space Available

Space constraints can greatly influence your equipment choices. In areas with limited space, compact or multi-functional equipment might be the best fit, allowing you to maximize efficiency without sacrificing performance.

On the other hand, if you have plenty of room, you might opt for larger, more specialized machines that can handle higher volumes or more complex tasks. Always measure the space you have available and consider the equipment's footprint, including any necessary clearance for operation and maintenance.

Here are a few additional considerations:

1) Vertical Solutions: If floor space is limited, consider equipment that utilizes vertical space. Vertical conveyors or stackers can significantly increase your storage and handling capacity without expanding your footprint.

2) Mobility and Flexibility: For operations where the layout may change or equipment needs to be moved regularly, look for options that offer mobility. Portable conveyors, for example, can be moved to where they're needed, making them ideal for flexible production environments.

Taking into account these additional points ensures that you choose equipment that not only fits physically but also aligns with the operational dynamics and future scalability of your facility.

Evaluate Equipment Durability And Maintenance

Durability is vital in bulk material handling equipment. High-quality, durable equipment may come with a higher upfront cost but can save you money in the long run through reduced downtime and maintenance costs.

In addition, consider the maintenance requirements of the equipment. Doing so will help you set up a predictive maintenance plan. Plus, easy-to-maintain equipment can reduce downtime and keep your operations running smoothly. Look for machines with accessible parts and straightforward maintenance procedures.

Focus On Energy Efficiency And Environmental Impact

Focus On Energy Efficiency And Environmental Impact

Focusing on energy efficiency and environmental impact not only supports sustainability goals but also translates into significant cost savings over the equipment's lifetime. Equipment that requires less power to operate or can utilize renewable energy sources minimizes your carbon footprint while reducing energy bills.

Moreover, choosing equipment that generates less noise and fewer emissions can help you meet stringent environmental regulations and contribute to a healthier workplace and community. This proactive approach towards energy efficiency and environmental stewardship is not just good business practice—it reflects a commitment to the planet and future generations.

Look For Versatility And Adaptability

Versatile equipment that can handle multiple types of materials or perform various functions can be a smart investment, especially for operations that involve a diverse range of materials. Additionally, equipment that can be easily adapted or upgraded can extend its useful life and adjust to changing requirements without the need for complete replacement.

Understand Safety Features And Regulations

Safety should always be a top priority. Choose equipment that comes with built-in safety features to protect your workers and comply with all relevant safety regulations. This includes guards, emergency stop features, and dust control systems, among others. Ensuring your equipment meets or exceeds safety standards can help prevent accidents and reduce liability.

Compare Costs And Consider Financing Options

While cost shouldn't be the only factor in your decision, it's undoubtedly an important one. Compare the initial purchase price of different options, but also consider the total cost of ownership, which includes maintenance, operation, and potential downtime costs. Some manufacturers offer financing options, which can make high-quality equipment more accessible by spreading the cost over time.

Conclusion

Choosing the right equipment for bulk material handling is essential for operational efficiency and safety. By thoroughly understanding your materials, assessing your needs, and considering factors like durability and energy efficiency, you can make an informed decision that supports your operations now and in the future. The right choice not only optimizes your processes but also contributes to sustainability and cost savings.

We use cookies to ensure you get the best experience on our website. Read more...