Cured-in-place pipe (CIPP) lining is an innovation gaining popularity in solving pipe damage issues. It’s a non-invasive technique since it doesn’t require digging to access the damaged pipe and replace it. With CIPP, you’ll repair your damaged pipe from its current position.

What Is The CIPP Procedure?

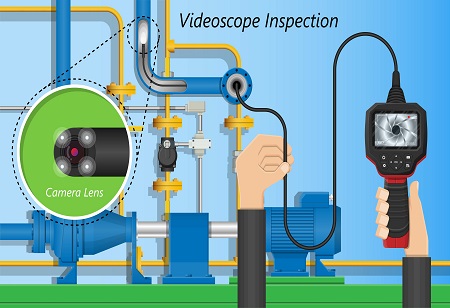

Your chosen CIPP professional will inspect your damaged pipes using a pipe inspection camera. The inspection aims to identify the damaged areas and see the extent of the damage. With this information, the team will proceed to manufacture the lining they’ll need for the repair off-site.

Once the lining is ready, they’ll return to your premises to install it. First, they’ll flush water down your damaged pipe at high pressure to clean it. You want the surface of your pipe to be clean for adequate bonding with the lining material. The CIPP experts will then insert the lining material into the damaged pipe until it gets to the end of your pipe. They’ll then invert the lining such that the outer side of the lining becomes the inner surface.

Curing is the next process, which is the hardening of the liner against the surface of your damaged pipes. This process more or less creates the new pipe that you’ll utilize.

As a client considering this pipe repair process, are you wondering if this solution is long-lasting? This article will help you answer this question by discussing the factors that affect the longevity of the CIPP solution. They are as follows:

The Quality Of Your Lining

As stated earlier, the CIPP professionals will manufacture the lining off-site. For effective

cured-in-place pipe lateral lining, the manufacturing of the lining has to be done right.

The manufacturing team has to impregnate a felt material with resin to strengthen it. The team can use vinyl, epoxy, or polyester resin. Each of these materials has areas where it works best, providing the ideal solution.

Therefore, the team has to adopt the right one for your piping needs for it to last for a long period. For example, vinyl resin should be your choice if you need to protect your pipe from rust. On the other hand, epoxy resin is ideal for indoor pipe repairs since it doesn’t emit toxic fumes.

After the impregnation, the professionals must coat the exterior with polyurethane to form an impermeable membrane. Failure to do so will likely result in leaks over time, affecting the durability of your solution.

The Expertise Of The Team You Hire

CIPP isn’t your everyday plumbing solution. Not all

plumbers can execute this procedure efficiently. Special training schools exist to provide training on how to do this correctly. Hence, your chosen CIPP team must be qualified for the job.

With their special training, the team will have the right skills or know-how to handle your CIPP repair needs. Therefore, they’re less likely to make errors during the installation process, allowing the repaired pipe to stand the test of time. On the other hand, the wrong installation will render your CIPP solution useless after some time. This might take you back to square one, which is undesirable.

The Curing Process

As previously stated, the curing process aims to harden your lining to form a new pipe. The efficiency of this process directly impacts the longevity of your CIPP repairs.

There are several curing

innovations the team of experts can adopt. These are hot water, steam, ultraviolet (UV) light, and ambient curing. How do these techniques work?

Hot water curing involves passing hot water through the lining, while steam curing requires passing steam. On the other hand, UV light entails passing UV rays along the length of the lining, while ambient curing is where you depend on the surrounding temperature to cure the lining.

All four techniques require passing a specific catalyst along the length of the lining. The length of time that the catalyst is passed through the lining will determine the effectiveness of your curing. In other words, passing the catalyst for as long as possible allows the lining to harden sufficiently against your damaged pipe. If you fail to devote enough time to this process, the solution will be inefficient for long-term use, causing new or recurring pipe issues.

Also, for a durable solution, you must ensure the catalyst reaches the other end of your damaged pipe. You don’t want cold spots along your lining. Furthermore, it’d help to use the right pressure to pass the catalyst along the lining’s length.

Conclusion

The discussion above has shed light on the essential factors that affect the durability of your CIPP lateral pipe lining. For a long-lasting solution, it’s essential to hire experts, execute the curing process correctly, and use a quality liner. Ticking all the boxes will ensure an excellent repair job, allowing you to get value for your money.