Over the years, the Indian market for springs is becoming more mature in terms of the design requirements with more complex product manufacturing being moved to India. Also, as India is positioning itself as a global manufacturing hub, it is expected to witness a huge growth in the automotive, electrical, and general engineering sectors.

Therefore, there is a huge potential for the local spring industry to be part of an import substitution program and locally manufacture springs and also bring down costs considerably for local product manufacturers and OEM’s. All this warrants for more critical spring designs with higher accuracy and consistency.

Prioritizing quality, reliability and repeatability, Rohit Springforms has been one such player in the industry who is a well renowned international supplier of bespoke springs, sheet metal parts, and copper coils. Based out of Pune, the company ensures a proper data is available before starting any development.

Having an experience of more than 35 years now in the industry, the company has been robustly placed in precision small spring manufacturing for wire diameters ranging from 0.10 to 8mm, and

also areas where the end applications require high reliability and repeatability.

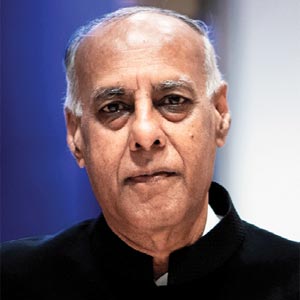

“We are very keen on taking on challenging projects, and at the same time, price our products aptly by aligning the QCDS [Quality Cost Delivery and Service],” says K.V. Raghavan, Founder & Director of the company. “We also take care of all aspects of development at the initial feasibility stage itself and do not compromise on the need to invest in new machines/accessories at the initial stage itself,” he adds.

Technically Adept Team

Furthermore, their technically skilled and qualified team has always been a core strength which ensures not only customer satisfaction but customer delight as well. They have mustered needed capability to offer a basket of products with springs and stampings, wherein, they integrate the two to offer customers with value added services by supplying the sub assemblies itself.

The company is well equipped to manufacture a variety of springs, precision stamping parts (Multislide stamped parts as well as progressive die stamped parts) and magnetic induction coils. “We believe in a long term association with our customers and offer a one stop solution for springs, copper coils, stamped parts, multi-slide parts and offer sub assemblies as well,” says K.V. Raghavan.

State-of-the-art Facilities

Currently, the company has manufacturing units setup in Pune and Bangalore, while their Pune facility is more than 35 years old now. Both plants have a very good stable and experienced team of engineers, tool makers, executives and being headed by very capable techno commercial plant managers. Also, these plants have similar facilities and serve as a contingency to each other in events of exigencies in one of the plants.

The combined efforts of both the teams have kept them in the right trajectory, wherein every team member is self motivated in achieving the company objectives. Furthermore, the company has been consistently investing on modernization and new product development. They are working toward its growth in developing sub assemblies, creating new product portfolios and strengthening its presence in bigger coil springs [5mm to 9mm wire diameter].

“We are locating our manufacturing facilities closer to major customer facilities and developing alternative ways of doing business by sharing resources to optimize yield, distribute costs on a larger base to keep the indirect costs as low as possible. Social Media in today's age is a big marketing tool and the company is gearing up to increase its presence in the social media space and offers various new services related to the spring manufacturing industry through this social media platform in the near future,” concludes K.V. Raghavan.

We use cookies to ensure you get the best experience on our website. Read more...