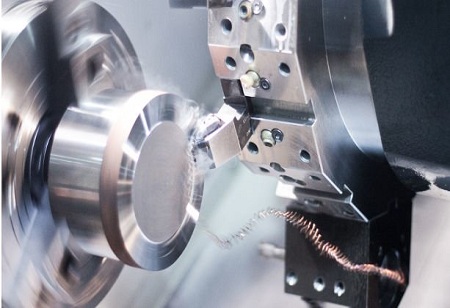

Having played a crucial role in component manufacturing,

CNC machining has proved to be a significant contributor to the manufacturing ecosystem. Owing to its importance, the market is expected to grow at a CAGR of more than 7 percent. This growth can be attributed to the increasing need for intricate solid parts of specific shapes. As the parts makers look for enhanced efficiency, they are looking towards CNC machines as they are providing them with automation and accuracy.

With time, the CNC machining technology is getting more advanced as we are seeing increased usage of automatic tool changers and multi-axis machining technology. In addition, sensors are being used to connect CNC machines to the factory floors, giving real-time information regarding the status of equipment being made so that the factory floor activities can be marshalled accordingly. It also works the other way wherein the factory floor can inform the CNC machining section

regarding the need for certain components, the production of which can then be planned accordingly. The sensors also give information about the productivity levels, efficiency and energy storage of CNC machines.

Boosting the accuracy and efficiency

Some of the industries which are seeing increased demand for CNC machining are aerospace, automotive, medical, and the defense industries. In these industries, there is high demand for manufacturing of complex components of different size and shape such as the blades for wind turbines. Looking to meet this demand, manufacturers are gearing up to innovate to boost the accuracy and efficiency. The end goal is to produce component of any size, any time as per the demand. The sector which is witnessing highest growth is the automotive sector. Aerospace is the other segment which has a similar demand for CNC machining.

“Customers are looking outward for business as automation is bringing in better quality standards and specifications and exports seem a better option due to weak domestic demand. The onset of BSVI domestically has boosted customers to invest in precision machinery where quality is guaranteed without human intervention and high productivity & throughput,” says Gururaj Patil, MD, EMAG India.

Although this year the manufacturing sector saw a dampened activity, it quickly picked up pace and is limping back to normalcy pretty fast. Being the fundamental growth propeller for the manufacturing industry of finished goods, the CNC machining sector is lending the helping hand and the advancement in this area in bound to reflect in the efficiency of finished goods manufacturing as well. Moving forward, the rapid advancements in CNC machinery are going to lead the way in the near future.