Demand for

graphite has grown rampantly as scientists as well as manufacturers have discovered that the unique capabilities of graphite lend themselves well to applications in the world of technology & electronics. Although graphite is already one of the key components in lithium-ion batteries for laptops, mobile phones as well as electric cars, it is being explored as an organic, and a highly flexible alternative to the materials which are used in the manufacturing of solar cells.

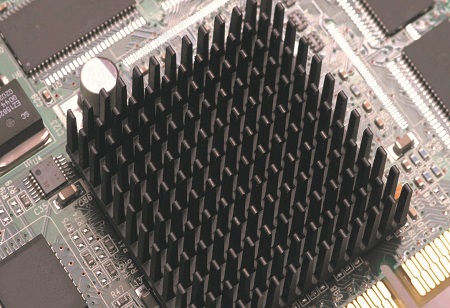

What makes graphite a great material for

electronics applications is the unique ability of the material to conduct electricity while either dissipating or transferring heat away from critical components. These include semiconductors, electric motors & even the production of modern-day batteries.

Currently, research is being conducted on how the useful properties of graphite as well as the carbon monolayer materials could be harnessed for improving modern technology, that include flexible touch screens for electronics devices, sensors, DNA sequencing & fiber-optic cables.

Some of the significant applications of graphite in modern electronics industry include:

Nanotechnology & semiconductors

As devices & electronics are becoming smaller in size, carbon nanotubes are becoming the norm, & are proving to be the future of nanotechnology & the semiconductor industry. Graphene - the single layer of graphite at the atomic level are being rolled up & used in nanotubes & this is likely owing to the impressive electrical conductivity & the exceptional strength & stiffness of the material.

At present, carbon nanotubes are built with a length-to-diameter ratio of up to 132000000:1. This is notably larger than any other material. Apart from being leveraged in nanotechnology that is still rather new in the world of semiconductors, it should be kept in mind that most graphite manufacturers have been particular about making specific grades of graphite for the semiconductor sector for decades.

Electric motors, generators & alternators

Carbon graphite material in the form of carbon brushes is also frequently being implemented in electric motors, generators as well as alternators. Here, in this case a "brush" is nothing but a device which conducts current between stationary wires & a combination of moving parts and it is most often housed in a rotating shaft.