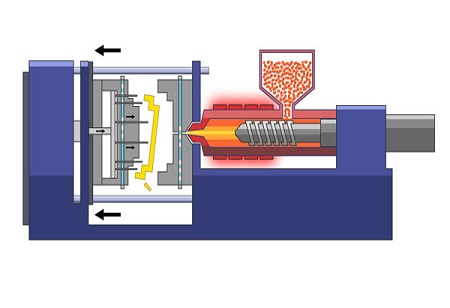

Ever since the advent of injection moulding, the shape of the object that can be moulded has known no bounds and it has opened new avenues for several industries, especially the

packaging industry. Accuracy, automation, and speed are some of the attributes that are driving the increasing adoption of

injection moulding machines. The modern moulding machines have shown their efficacy in producing parts of complex geometries and which can withstand extreme pressure of the environment in which they are going to be used.

Along with the high output, the rise in the quality of products has significantly increased the adoption of high-tech injection moulding machines. With the advent of automation, new machines have the capability of running the injection moulding process without being operated manually. The moulding process runs in an automated fashion, churning out the product according to pre-set parameters and standards.

If we compare this transition with the traditional moulding methods, it is momentous change in the form of quality and speed of production. Moreover, the products with intricate shapes and sizes needed for today’s varying requirements were nearly impossible to produce with conventional moulding processes.

Automation and Robotics

Automated injection moulding machines have a sequence of operations aligned properly to ensure stability and productivity while ensuring precise usage of material and no wastage whatsoever. With time, the level of automation used in injection moulding machines is expected to go up and we are going to see the application of robotics in this field as well. With these technologies, the injection moulding machines are becoming even more precise and accurate. Higher productivity with accuracy is what is required to meet the growing demand for injection moulding as the increasing urban population is going to catapult the demand for packaged goods combined with the effects of rising e-commerce.

“Injection moulding is an area of manufacturing that has seen significant technological development in recent years. The sustained evolution of accuracy and control levels for all-electric machines, combined with increasingly sophisticated automation systems, has stimulated growth across a number of sectors,” says Tom Bouchier, Managing Director, Fanuc UK.

There is an increasing competition to have quality packaging as research suggests that packaging has become an important factor in driving sales and influencing customer. This has compelled sellers to adopt new types of packaging, more so after the increased hygiene consciousness of customers. As a result, rigid plastic packaging has shown high demand and the same is in turn has multiplied the demand for injection moulding machines.