The electric vehicle (EV) industry in India is witnessing rapid growth and with sales of EVs scaling new heights every month since mid-2021. With well over three lakh EVs sold last year, the government, too, is doubling down on electrification of mass mobility solutions, rolling out the production-linked incentive (PLI) scheme for battery cell manufacturing and announcing a battery swapping policy as part of Budget 2022.

However, while boosting production of and generating demand for EVs are both receiving due attention and the recycling of EV batteries, too, needs to be addressed, as such batteries, if discarded improperly, can pose a serious threat to the environment.

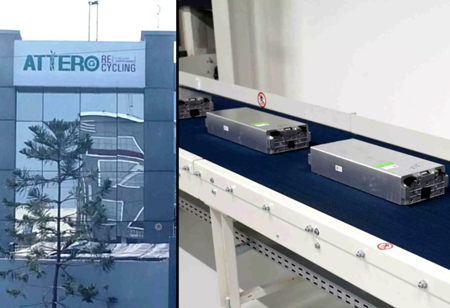

Attero Recycling, one of the biggest electronic waste recycling firms in the country today, knows the number of batteries from EVs that will need to be recycled will grow exponentially in the time to come, and so, is in the process of setting up a brand-new lithium-ion battery recycling plant, which will boost its EV battery recycling capacity from the present 700 metric tons to 11,000 metric tons.

"We are in the process of expanding the capacity of both the e-waste business as well as the lithium-ion battery business. The e-waste business capacity, we're in the process of doubling from a current capacity of 1,44,000 tonnes to almost three lakh tonnes, and the lithium-ion battery capacity we are increasing by over 11 times to almost 11,000 metric tons within this calendar year", said Nitin Gupta, co-founder and CEO of Attero.

Gupta said the costs involved with setting up an Attero lithium-ion battery recycling facility, which recovers battery-grade outputs of cobalt, nickel,

lithium carbonate, manganese oxide and graphite, are the lowest in the world, undercutting similar setups across the world by as much as 35 percent.

Even though EVs have only found acceptance in India in recent years and are still relatively limited in numbers, Attero says the supply of lithium-ion batteries that need recycling – including from other industries – is quite high. It is the electric two- and three-wheeler segments that are witnessing immense growth at present, and while their sales are not level with their combustion engine counterparts, Gupta says recycling EV batteries is already a profitable exercise for Attero today, thanks to its advanced recycling technologies and soaring demand for raw materials that make up an EV battery.

"On an average, we have access to around 2,000 tonnes of lithium-ion batteries, which are end-of-life and available to us for recycling in India, on a monthly basis. Our lithium-ion batteries business today, even if you only consider batteries sourced from EVs, is profitable and cash-flow positive. This is because our extraction efficiencies are so high and the technology so superior globally, that we're able to generate a significant amount of cash", Gupta said.

At present, Attero sells valuable metals obtained from lithium-ion battery recycling to the steel, chemicals and medical industries, and targets sales of these metals to cell manufacturers abroad from the second quarter of this year. However, once local cell manufacturing firms are established, they will become the biggest clients for domestic recyclers in more ways than one.

"All the cobalt that's mined in the world, a majority of it that goes to the lithium-ion cell manufacturing firms, and the same goes for carbonate, graphite and nickel. So, yes, cell manufacturers in India will be our biggest consumers, and additionally, once cell manufacturing facilities are set up in India, all of them will generate manufacturing waste, which is eight to ten percent of production capacity. So, they will also become an input feeder for our recycling plants", said Gupta.

For now, Gupta is optimistic about the battery swapping policy and its implications for the battery recycling industry, as he estimates the number of batteries that will need recycling in the coming years will almost triple, given the nature of the battery swapping model for EVs.

"The swapping policy is a positive development. From a recycling perspective, there will be three times the number of batteries that will need to be recycled, as there will be one battery on the road, one in the charging network and another reserved as a backup battery", adds Gupta.

Attero has therefore already tied up with MG Motor India for recycling batteries that will be recovered from its electric SUV, the MG ZS EV, and is also working with other EV players, including Hyundai and Tata Motors.