Traditionally, the sheet metal fabrication industry includes processes like cutting, machining, welding and assembling an end product. For a long time, this industry has been present and acts as an important link for the production of many consumer products. With technological innovations happening rapidly, the usage of fabricated metal is also becoming diverse. They are being adapted by high end industries like automotive, aerospace, energy, and infrastructure and constructive and several others. The pattern in the demand for metal fabricators has also been a subject of drastic change as, now every player in this industry has diverse clientele and has integrated advanced technologies in their production and supply chain processes.

Automation

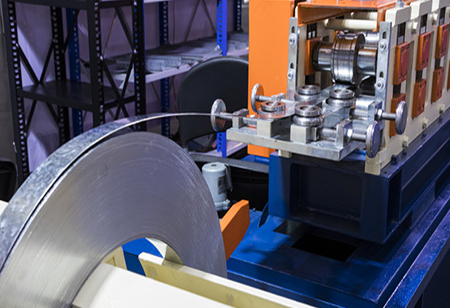

Automation has changed the outlook of the business ecosystem in a revolutionary manner and the metal fabrication industry is no exception. It has completely changed the production process for all the metal fabricators worldwide. The process of cutting and welding of customized material is now possible using the minimum effort with the help of automation. It is, as if the factories are running on machines. From the basic to the finishing of the material, every process is

getting automated. Moreover, processes can be completely left up to the machines without any kind of human supervision.

3D Modelling and Printing

3D technology has changed the face of many industries and especially in the pre-engineering side of things. May it be construction of a super structure or the construction of a new machine, 3D modelling has greatly facilitated the production process by providing 3D models of the exact type of fabrication required. Once the model is ready, it can very easily be used as a template to create the exact structure that is necessary for the construction. When it comes to the industry of metal fabricators, the technology of 3D modelling has made them create pre engineered models for products that are required by clients. Once the model gets approved, production becomes a ball game. However, 3D modelling and printing is relatively new to the spectrum and is still undergoing adaptations in the industry.

Nearshoring

Growth in native demand is one of the primary trends that is helping the metal fabrication industry grow. For a long time, the traditional thinking of big manufacturing companies was to get their products fabricated and delivered by Asian countries like China and India owing to the low labour cost and perfection in material. But now, as the native demands are increasing, the fabricators in the country are led to comply with the businesses in the home country. So, a lot of countries are again coming back to nearshoring and producing in their respective countries. Make in India movement, launched by Pm Narendra Modi has been one of the prime facilitator of native production for several industries.

ERP Adoption

The adaptation of technologically advanced ERP (Enterprise Resource Planning) systems has also resulted in the growth of the metal fabrication industry. It is a known fact that metal fabrication is conducted across geographies that has a complex supply chain structure. Modern ERP software has the capability to bring every business operation under one umbrella that can result in better functioning of the business.