In an interaction with Industry Outlook, Mahesh T S, MD, Aadhya Airtek discusses the fast expansion of the HVLS (High Volume Low Speed) fans market in India. He describes how the growing emphasis on energy-efficient cooling, workplace comfort and automation is driving the growth of HVLS fans. He highlighted the benefits of HVLS fans over traditional options, their contribution to energy savings, and their effect on industrial productivity. With over 30 years of experience, Mahesh T S‘s expertise in the fields of electrical, electronical and mechanical services industry is adding value to the growth of Aadhya Airtek as a leading player in India.

How do you see the current evolution of HVLS fans market in India?

The evolution of HVLS fans market in India can be traced back to 2009-10. The fans which were initially developed for the purpose of cowsheds gradually made their way to huge spaces like airports, railway stations and in a span of 10 to 12 years have penetrated into industrial and commercial spaces convention centres, religious institutions, restaurants, production areas, workshops, auditoriums, etc. With sustainability taking centre stage, the day is not far when these fans will be a household name all over the world.

How do HVLS fans provide a cost-effective solution to maintain fresh air circulation in large facilities?

As a rule of thumb, a smaller fan consumes less suction pressure, whereas larger fans need higher pressure. Upon the initiation of air tumbling, the ambient temperature stabilizes. For example, if the ambient temperature is 35 degrees, operating an HVLS fan for one hour—broken into four cycles of 15 minutes each—can lead to a temperature variation of about 3 to 4 degrees. This provides a consistent ambient temperature, which increases the comfort of the space for individuals.

2 years ago, we did a project for an automobile manufacturing company in Bengaluru. There were around 30-35 small industrial fans that were installed for a 7000 sq. ft. space. These fans were consuming around 9-9.5 kw of power per hour contributing to 128 dB noise levels. Later, for the same space we installed on 20 Ft HVLS Fan which consumes 1.5 kw of power per hour contributing to a negligible 35 dB noise level.

A number of fans will increase power consumption, adding to noise levels without providing sufficient comfort to the end users. In contrast, HVLS Fans reduces power consumption, increases airflow with uniform air distribution adding to negligible or zero noise levels (depends on motor) and provides better comfort to the end users.

How do HVLS fans differentiate themselves by directly contributing to improved productivity? What kind of change in employee well-being have you seen by the implementation of HVLS fans?

In the industrial sector, better air circulation directly adds to increased productivity. In conference halls, where large rooms are occupied by people, HVLS fans assist comfort by effective air distribution across the room. Wall-mounted fan (Side walls), smaller fans typically also have a smaller throw of 10 to 15 feet. If the area is broad—e.g., 60 to 80 feet in width—these small fans fail to reach the centre effectively. HVLS fans, however, give complete air circulation, reaching every corner of the room.

In a specific industry, there were approximately 16 to 18 fans installed to supply airflow for 20 to 25 workers who worked on different machines. There was a fan per machine, and the total count was about 18 fans. These minor fans were not capable of giving sufficient airflow, used more power, and produced a lot of noise.

In such cases, we have installed only one fan, and this covered the entire working space successfully. All operators and employees received equal air distribution and better comfort while on duty. The HVLS fan served efficiently over coverage of around 6,000 to 7,000 square feet with equal airflow everywhere, no matter where employees moved or in which direction. Because of these benefits, a lot of industries are adopting HVLS fans nowadays.

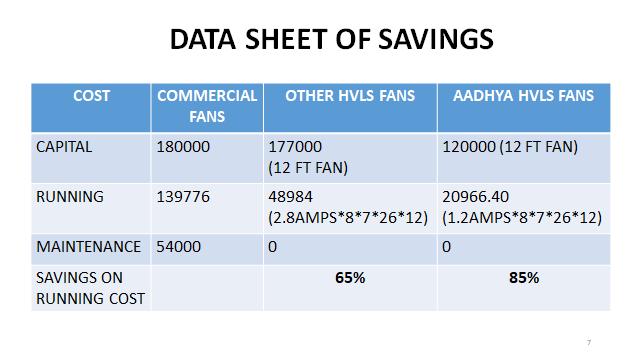

This question reminds me of a study undertaken 6 years ago when we were into R&D with respect to these fans. We did a project for an automobile spare parts manufacturing company in Bengaluru. The production floor was divided into bays. Each bay consisted of 12 workers in 240 sq. ft. of area. There were around 8 bays with 96 workers in 1920 sq.ft. of area. Approximately, around 90 fans were installed of 15” size. If the fans cost around 2000 Rs then the capital cost would come up to 180000 Rs.

When we calculate the power, if each fan consumed 40 watts of power, then with 90 fans the power consumption would be around 3600 watts which would be around 5 hp power. 1 hp is equal to 1.6 amps and hence, 8 amps per hour were used. If one shift runs for 8 hrs, then 8 bays consume 64 amps per hour (7 Rs per unit) adding up to power expenses of 448 Rs. Per hour, 11648 Rs per month, and 139776 per year. Even if the maintenance cost was calculated at Rs. 50 per fan per month, then for 90 fans in a year, the company would be spending around 54000 Rs per year.

Following this study, Aadhya fans produced the following results:

How do HVLS fans balance the high performance along with the low operational noise?

For industrial use, we have an induction motor with a gearbox, which produces around 30 to 35 dB of noise. If it is a higher height, that noise also will be negligible. Moreover, in the industries, the noise level will be somewhere around 120 dB. Our fan noise is 35 dB. So, it's negligible for the industry.

For auditoriums, or some many other peaceful places like meditation centres, there are PMS (Permanent Magnet Synchronized) motors. They are zero-noise motors. In the same cases, for smaller fan applications, there are BLDC (Brushless DC) motors, which too run silently. Even ordinary home fans produce some form of noise, but there are BLDC and PMS motors that offer zero noise. Where required, a choice of a PMS motor or a BLDC motor guarantees smooth and silent operation over more hours of continuous usage.

The noise level of a fan depends on three factors – the blade span, the initial torque it takes and the motor capacity. For example, a 1.0 hp induction motor with 43 nm (torque) is not sufficient for a 16 ft fan due to which it produces noise whereas a 1.5 hp motor with 128 nm (torque) is sufficient which reduces the noise level of the fan.

How do HVLS fans complement the existing HVAC systems?

In an air conditioning system in HVAC, consistent cooling of large spaces with high ceilings is a problem. One of the most important considerations is the tumbling of air. Cool air, as it is discharged from the duct and flows down towards the floor, tends to cover a distance of approximately 10 to 20 feet. At the same time, hot air will be flowing up, thus having a circulation pattern. But in a few minutes, the temperature of the cooling air can vary with this tumbling effect.

In order to maintain the whole space cooled, the air conditioner has to be cooled at a lower temperature, usually at 18-degree temperature. At such setting, the compressor runs constantly without turning off, resulting in greater energy consumption. Through the integration of an HVLS fan with the HVAC system, the circulation of air is greatly improved. With the HVAC temperature at 24 degree or 26 degree and the use of HVLS fans, airflow distribution becomes more effective. The fan works to push down cool air and ensure good circulation.

Let us take an area of 8000 sq.ft. for example. Normally, it will require around 61.5 tons of AC (Inverter AC). Based on the number of people and machinery in an industrial space, with a 30% hike, for comfort, we suggest around 80 tons of AC. The capital cost for 80 tons of AC will be around 28 Lakhs. For the end users to feel comfortable, let us keep the AC at 18 degrees. Then, every ton of AC consumes 1.25 kw of power and hence, 80 tons would consume 100 kw of power which comes up to 8 amps per ton. The result is, 800 units of power is required per hour, and at 10 Rs. The expenses will come up to 8000 Rs. Per hour, 64000 Rs per day and so on.

For the same space, if one 20 Ft HVLS Fan is used along with AC, then it complements and saves power as follows:

When 20 Ft Fan is used, 60 Tons of AC will be enough saving 20 Tons of AC. It would be enough if the temperature is maintained at 24-degree. Therefore, 25 kw of power will be saved. A capital cost of 700000 will be saved. Assuming maintenance at 10% of the capital cost, around 70000 per year will be saved. And power savings will be around 16000Rs per day. Moreover, there will be a uniform distribution of air.

How do you see the future of this market? How is it going to evolve further in the in the near future?

In the near future, there is a high demand for HVLS fans with aesthetic-wise. Owing to the wide size of our fans, it is not possible to use sheet metal because it is too heavy. We are rather using aluminium that is light but strong. To address customer needs, we provide different finishes like anodizing, powder coating, and spray painting. Moreover, we are now launching PVC wings filled with PUFF material, which lightens the weight considerably while maintaining structural strength and avoiding sagging. In addition, we are now diversifying our product line to introduce green and sustainable products.

The HVLS Fan industry in India has rapidly moved from the infancy stage to the growth stage. We are also looking forward to adding a designer touch to these fans specifically for the domestic domain and PVC fans developed out of recycled material to contribute towards sustainability and leave our footprints to make the earth, a greener one.

We use cookies to ensure you get the best experience on our website. Read more...