The industrial fasteners industry in India is massive with diverse fastener types and sizes designed for various applications. The industry, valued at $9064 million in 2022, is expected to expand exponentially and reach a value of $17,868 million by 2030. This growth is anticipated to be the result of growing domestic and export demands. As India embraces more industrial production across different industries including automobiles, consumer electronics, and more, the demand for fasteners is growing rapidly. Moreover, the increasing infrastructure projects further propel the demand for these products. The introduction of MIP (Minimum Import Price) is also adding a boost to the industry.

However, raw materials shortage or inconsistency, shortage of labor, and logistical management are some significant challenges that need to be addressed. Royal Anchors, a Chennai-based Anchor Foundation Bolt, Sag Rods, Brace Rod & Connection fasteners manufacturing firm is tactfully addressing these issues, by maintaining a wide range of stock of raw materials, housing adequate labor force, and forging partnerships with logistics businesses, to ensure a seamless supply of products, and to offer more value to customers.

Customization for Every Application

Specializing in customized solutions for every client, Royal Anchors stands out for its ability to tailor every Bolt/Sag Rod/Brace Rod as per the specific requirements of the consumers. The company provides a range of customized anchor foundation bolts, sag rods, brace rods, and connection fasteners directly to PEB manufacturers, government agencies, fabricators, erectors, and subsequent allied industries.

The firm manufactures products as per the American (ASTM), British (BS), and Indian standards, translating these into the closest Indian standard equivalent and carrying out production from scratch as per the unique guidelines. From choosing raw materials as per these standards to manufacturing the bolts, the complete process is tailored to produce the desired outcome.

To assure precise production, the firm undertakes a comprehensive approach to manufacturing, collaborating closely with clients to understand and verify their needs. Customers are asked to provide approved drawings and specifications by a verified consultant, of the application for which the bolts are to be used. Thereafter, a thorough questionnaire follows, aimed at understanding the accurate measurements, material quality, tests to be conducted, and other details about the product to be manufactured.

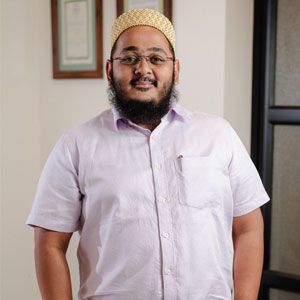

“We like to mention that we are like tailors in this industry, customizing products from scratch. Clients can come to us with any kind of specifications and we will create the products to match their exact requirements. We do not make standardized ‘one size fits all’ solutions. We pride ourselves in the fact that we add value to clients by providing unique products to cater to their precise needs”, shares Huzefa Johar, Co-founder, Royal Anchors.

After gaining this information, the manufacturing process starts. Throughout the manufacturing phase, customers are provided complete transparency and a test certificate number for the raw materials.

Clients can assess the purity of the materials through these measures at any time. Post completion of the manufacturing process, the company packages the products carefully and provides door-step delivery to clients, becoming not just a product vendor, but a comprehensive solutions provider.

“We understand that based on our delivery commitments, clients line up their other operations, and as such, we plan our solutions and make commitments accordingly to ensure they do not have to incur extra costs in case of our failure to deliver. When clients come to us to purchase products, we like to ensure that they are 100 percent satisfied with their selection in choosing us. We believe in providing a completely stress-free purchasing experience and like to focus more on providing a service”, further adds Huzefa.

Multi-Step Quality Inspections

For the purpose of ensuring that every product manufactured is durable, up to industry standards, and safe for use, Royal Anchors undertakes multi-step quality assurance processes. The first inspection is done when raw materials arrive at the facility, ensuring that the grade of the raw materials matches the requirement for the particular batch of products.

Royal Anchors adheres to the philosophy that quality should be at the core of all corporate operations because it is essential to an industry's health

“Quality is of utmost importance to us, we are committed to constant improvement across the board to help us achieve our goal of complete client satisfaction. We house world-class machinery for the production of certified quality products. We have created a thorough quality assurance system that enables our business to satisfy all of the requirements of ISO 9001:2015 quality management system standard”, adds Huzefa.

Furthermore, throughout the production phase, various checks and inspections are conducted to test the manufacturing accuracy. Lastly, once the products are manufactured, a random selection of bolts and nuts is sent to an NABL lab for inspection. The third-party inspection conducted by an NABL certified lab adds an extra layer of surety and transparency in the quality of products, providing clients with peace of mind. Apart from third-party inspections, the firm also houses a testing lab that checks the products personally as well.

Future Roadmap

“At Royal Anchors, we adhere to the philosophy that quality should be at the core of all corporate operations because it is essential to an industry's health. Our mission is to empower industries through precision and reliability. Our vision is to be the leading manufacturer of industrial bolts and fasteners, setting the gold standard for quality, innovation, and customer satisfaction. We are committed to providing innovative solutions, maintaining the highest standards of quality, and fostering long-term partnerships with our customers, suppliers, and stakeholders”, lastly adds Huzefa.

Established in 2012, Royal Anchors, founded by Johar Shakir the father along with Muffaddal Johar and Huzefa Johar, brothers with a business background and a drive to build something of their own, has grown rapidly from a small manufacturer of industrial fasteners to one of the leading foundation and anchor bolt and non-standard construction manufacturer in India.

Driven by its motto ‘passion driven precision’, the company is dedicated to providing outstanding service and product quality to all customers, on-time deliveries, and an overall seamless and hassle-free experience. This dedication has played a significant role in elevating the company’s reputation from rookies to leaders, supplying products across India over the past years.

As the firm plans on its future expansion initiatives, it aspires to primarily increase its production capacity from a current 180 tonnes of product per month to 250 tonnes in the next few months, further scaling this up to 300 tonnes per month by next year. This endeavor is a particular challenge to accomplish since Royal Anchors only manufactures customized products. For this purpose, the firm is also planning to elevate the existing facilities and integrate more machinery as per the demand of the job.

Beyond this, the company also aspires to expand its geographical reach within India, particularly in the states of UP and Bihar, which promise immense infrastructural projects in the next few years, presenting a scope of massive growth. The firm has supplied its products for the construction of the Ram Mandir, and as the region attracts more infrastructure development initiatives, Royal Anchors aims to establish its visibility and become a supplier of choice.

With a multifaceted plan for expansion, a dynamic team at its disposal, and a passion for the industry, Royal Anchors, a leading name in the South, is poised to become a leading name across India in the coming years.

We use cookies to ensure you get the best experience on our website. Read more...