Over the past few years, industrial packaging solutions have evolved tremendously, driven by a confluence of factors, primarily focused on durability, innovation, and sustainability. The drive towards sustainability has acted as a fuel, powering innovation in this sector, supported by technological advancements that make it possible to curate solutions that are good for the planet, as well as for businesses.

The key factors shaping this industry include increasing push towards usage of recyclable materials, along with regulatory strictness to minimize plastic waste and to control carbon footprint, use of appropriate technology to control emission & leaching of chemicals into the atmosphere, rising business focus on sustainability to demonstrate the brand’s commitment to environmental stewardship, and consumer demand for sustainable packaging across all product categories. However, many businesses still face challenges with the limited variety of packaging solutions and the high costs of sustainable products available.

Determined to address these challenges and align with the positive trends, Bloom Seal Containers Pvt. Ltd. (BSCPL), a leading industrial packaging solutions company, offers high-quality, durable, and bespoke packaging solutions using world class proprietary barrier technology called Fluorination & in-house developed (TMBM) barrier technology using EVOH & Nylon which is 100 percent recyclable. Focused on innovation, sustainability, and customization, the company is positioned as a pioneer, developing cutting-edge solutions for diverse applications.

Flourishing through Innovation

Since 1994, Bloom Seal has shaped the plastic industry in India, and stands as a distinguished manufacturer of comprehensive industrial packaging solutions. An ISO 9001: 2015, US DMF Type III, and ISO 15378 certified organization, Bloom Seal is renowned for offering a wide range of HM/ HDPE containers from 50 ml to 60 ltr capacities, suitable for use in diverse industries like agrochemicals, fine chemical, lubricants, ink & paints, veterinary chemicals, flavor & fragrance and more.

Innovation being a key motivator, the company has carved an unrivaled position for itself by introducing game changing innovations like a new version of the floating solar platform, incorporating high ratios of recyclable and recyclable HDPE, into its products without compromising on performance. Designing light weight packaging containers that use less material while maintaining durability, Bloom Seal has also developed Plasma based fluorination process that further reduces environmental impact while boosting chemical resistance.

“We stand out in the market by adopting cutting-edge manufacturing technologies, including injection molding, blow molding, and proprietary innovations like fluorination of HDPE products which is 100 percent food grade and recyclable, thus providing sustainable packaging solutions. Our technology of F2, our new development in Nylon and EVOH barrier technology and our

Plazma based fluorination process that are 100 percent recyclable help us optimize the container weights, putting plastic only where it is most beneficial, ensuring the solutions are optimal for industry use, without any wastage”, says Pradip Sagar, CMD, Bloom Seal.

The company has also improved safety features with the introduction of tamper-evident closures and child-resistant designs that are leak-proof, and spill-proof as well. Bloom Seal has also introduced products that are completely recyclable within the existing recycling systems, while also ensuring the packaging solutions are aesthetically pleasing by focusing on high-quality printing and labeling options that ooze exclusivity and premium appeal.

Catering to rising consumer awareness, Bloom Seal also has in-house developed complete digital integration of supply-chain traceability, to complete automatic manufacturing process, to 100 percent verified quality control before dispatch.

By boosting surface resistance through cutting edge barrier technology & by optimizing use of plastic, the company assists businesses in reaching their sustainability goals

Proprietary Fluorination Process

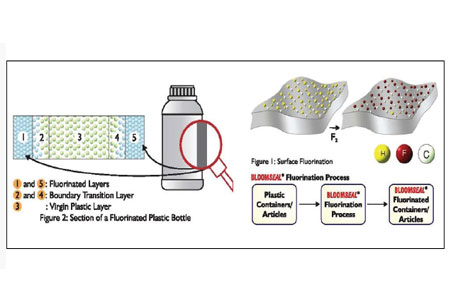

One of the key innovations that boost Bloom Seal's solutions is its proprietary fluorination process, performed by leveraging fluorination technology that helps enhance the chemical resistance of HDPE containers.

The technology effectively modifies surface-level properties of the material by creating a thin PTFE layer on top, which possesses the ability to resist aggressive chemicals, solvents, and other volatile substances. This, in turn, enhances protection of the surface against corrosion and degradation, making it ideal for sectors like agrochemicals, specialty chemicals, fine chemical, flavor & fragrance and more.

“Our fluorination technology helps businesses meet stringent industry requirements for safe, reliable packaging, making it an attractive solution for companies handling sensitive or aggressive chemicals. For industries like food packaging and other delicate chemicals, where contamination is a major concern, fluorinated HDPE containers ensure that the contents remain pure and unaffected by the container material. Additionally, by enhancing the chemical resistance, fluorination reduces the risk of leakage or container failure when storing dangerous or volatile substances, thereby enhancing safety during handling and transportation”, adds Pradip.

The technology is used in alignment with not just the industry standards, but also the unique customer requirements, which strengthens the firm to integrate specific features that the business requires. Moreover, by boosting surface resistance and preventing spoilage, the company assists businesses in reaching their sustainability goals.

Quality Focus

“Our focus on quality control, adherence to international standards like ISO certifications, and continuous improvements have played a pivotal role in solidifying our standing as a key player in the industrial packaging sector. Beyond this, we take a proactive approach to customer feedback and engagement, to ensure that our solutions are always in line with dynamic requirements.

We strive to incorporate customer suggestions into R&D and service enhancements, and treat customers as partners, which helps us make sure our solutions keep improving, and exceeding expectations. We’re proud to report that our Fluorination technology has achieved PFAS-free status, as confirmed by TUV’s rigorous testing protocols, made possible by our precise control over dilution elements”, concludes Pradip.

Future Roadmap

With robust infrastructure, skilled manpower, and a culture that encourages innovation, Bloom Seal has developed the perfect platform for driving growth that elevates the industry and heralds a new era of modernization in the HDPE and fluorinated rigid packaging sector. As the sector continues to expand and grow on the shoulders of sustainability, the company has built a strategic and comprehensive roadmap for the future that prioritizes these trends and propels the firm to new levels of success.

Bloom Seal plans to invest significantly towards sustainability initiatives, developing more innovative packaging solutions that are recyclable and help lower carbon footprint. Additionally, the firm will focus on enhancing fluorination techniques, in addition to developing multi-layer packaging solutions with minimal material usage to boost performance and minimize wastage.

Smart packaging solutions like IOT machines & manufacturing process enabled with interactive features, and customization and diversification of the product portfolio will also be important priorities for Bloom Seal in the coming years.

Alongside these, the company is targeting global expansion and strengthening its regulatory compliance frameworks with the evolving regulations. Through collaborations and partnerships with governmental agencies, technology providers, material innovators, and recycling firms, as well as customers, it plans to stay ahead of industry trends, making its mark as the frontrunner for innovation in this industry.

We use cookies to ensure you get the best experience on our website. Read more...