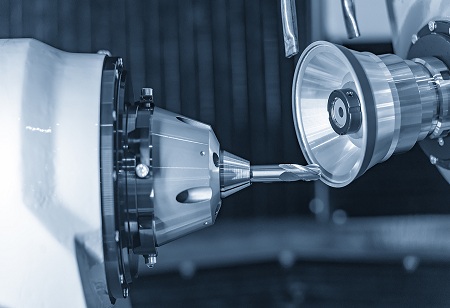

Precision machining produces the big and small objects that we tend to use in daily life, from automobiles to aircraft. Every object needs some level of a machinist’s skills. Likewise, a tool or machine that has been worn down can usually need machine activity, welding, or formation by a precision shop mechanic. From the assembly of vehicles to surgical devices and craft components,

precision machining is concerned in each technology and business. In short, if a product contains components, it needs some precision machining.

Successful precision machining needs the power to follow extraordinarily specific blueprints created by Computer Aided Design (CAD) or Computer Aided Manufacturing (CAM) programs. The

CNC machining technology creates 3D diagrams or outlines required to shape up a machine, object, or tool. The blueprints should be created with nice detail to confirm quality and success. Most precision machining corporations work with some style of CAD/CAM programs.

Advancements in machining technology and innovation-driven by high demand areas are pushing the machine business forward at a swifter pace. As per a report by Markets and Markets, the world machine business is anticipated to grow to a market size of $87.4 billion by 2027.

“The extensive implementation of CNC machinery across several industries has optimized an enormous range of manufacturing capabilities. It ensures extreme levels of precision, cost-efficiency, equipment safety and enables the mass-production of parts,” says Peter Jacobs, Senior Director of Marketing at CNC Masters.

Let us examine the factors that are pushing for the expansion of precision machining.

Machines-as-a-Platform

As CNC machines become a lot capable of execution difficult styles across a lot of axes of movement right away, the danger of collisions and machine injury will increase. This is often a key reason why machines-as-a-platform area unit growing in quality and importance.

Some of the leading service suppliers use computer-aided manufacturing (CAM) to make digital image of CNC instruments. Machine retailers, operators will transfer machine setups, specifications and path-finding instructions and feed in the required speed and style to execute on CAD designs.

There are two advantages to this. One is that it offers a retailer the means to check machine activity and products styles in strictly digital setting. The other is that it reduces the danger of injury and faulty components thanks to a poor match between activity and piece of work style. Moreover, style intent — together with tool alternative and finishing directions — is baked right into the digital models. No manual drawings are needed.

E-commerce to spice up the business

Companies usually faced an extended and troublesome method of procuring the correct inserts, mills, drills, and different materials and elements they have for the task at hand.

The benefits of e-commerce during this phase cannot be ignored. Online marketplaces make it easy for job retailers and makers to search out and get manufacturer-direct components, tools and raw materials with clear valuation.

Some leading businesses use a distinct manoeuvre by providing on-premise merchandising machines for repeatedly ordered components and machine elements. Over time, the products are reordered impulsively.