On January 5th, 2024, when a panel blew off a brand-new Alaska Airlines 737 Max mid-flight, leading aircraft companies have been under intense pressure since then. Although this event was the front & center for a specific manufacturer, it has spotlighted a series of safety as well as manufacturing issues which have piled up for the sector over the years. These events have placed conventional maintenance & repair procedures under focus & have augmented the need for advanced technologies to enhance the procedures. Although this event occurred in the United States, airline safety & maintenance are now in focus in various regions of the world and particularly for airline operations in India.

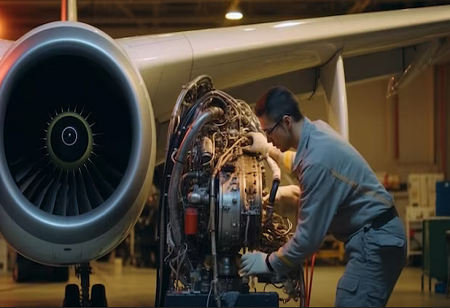

Efficiency, safety and innovation are paramount in today’s fast-paced world of aviation. To meet these demands, the industry has embraced a paradigm shift known as Maintenance 4.0 concept that blends cutting-edge technology and well-optimized processes to reshape the landscape of aircraft maintenance.

“Innovation and leadership are inseparable partners in the dynamic world of aerospace and aviation. As one of the most technologically advanced industries, it thrives on groundbreaking ideas and visionary leadership to propel it forward,” says Dr. Adarsh Kodhanda, the Founder & CEO of Aigen Labs.

Maintenance 4.0 is a revolutionary way of handling aircraft maintenance and is not just a buzz word which aims in making the whole process more efficient, intelligent & safer. Maintenance 4.0 seeks to use digital technologies at its core for streamlining the maintenance processes & transform the aviation sector. It is important to understand the relationship of maintenance 4.0 with Industry 4.0 for grasping the essence of Maintenance 4.0. While industry 4.0 is one of the broad concept comprising numerous advanced techniques & technologies which have revolutionized the manufacturing as well as the industrial process, Maintenance 4.0 is a specialized subset of the Industry 4.0 that is particularly customized to the unique needs of aircraft maintenance.

Maintenance 4.0 introduces numerous important concepts as well as technologies which drive its evolution. These include predictive maintenance which is the utilization of technology for identifying the components of an aircraft which needs maintenance beforehand. The appropriate software can pinpoint when a maintenance check will be needed accurately and this will be achieved by accessing real-time sensor data as well as maintenance logs. This helps in minimizing unscheduled downtime & timely maintenance.

AR/VR is revolutionizing training as well as inspection processes, where VR simulators help the maintenance personnel for practicing complex tasks in a risk-free environment. This helps in enhancing their skills without the requirement for physical aircraft. AR glasses aid technicians during repairs & inspections by overlaying digital information onto real-world views.

The virtual models of aircraft are created by digital twins and these can be used for simulating & analyzing performance in real-time. Digital twin technology helps in finding the potential risks prior to their occurrence and they optimize maintenance schedules & improve the complete operational efficiency.

Aviation InterTec Services renders industry-leading workflow consultation services for increasing efficiency, saving time & money. With decades of industry experience, Aviation InterTec Services helps in getting most out of the clients’ aircraft maintenance operations.

IoT & RFID are enhancing parts management as well as inventory tracking. The tags of RFID on the components allow for real-time tracking & monitoring and ensuring that the right components are available when required. This technology helps in decreasing the risk of inventory shortages & facilitates in maintaining the accuracy of the stock levels.

“While the MRO (Maintenance, repair, and operations) market for repairs and maintenance services for aircraft is expected to touch $4 billion by 2025, there is a scope for design and engineering services related to components and assemblies. Conclusively, the Indian aerospace industry is close to catapulting itself into a global arena with a rapid rise in demand for aircraft and components,” says Yash Gohel, Director, SHIVOM BRASS INDUSTRIES.

Aircraft inspections are transformed by drones that are equipped with high-resolution cameras as well as sensors. These drones can provide detailed imagery for assessment by accessing hard-to-catch areas and this significantly decreases the labor & time needed for inspections. For example, in order to reduce the inspection time from hours to minutes Delta Airlines has implemented drones.

LiDAR renders precise 3D scans of aircraft, and this allows for detailed assessments & inspections. LiDAR is specifically useful in measuring engine performance & detecting structural anomalies which may be invisible to the human eyes. It improves predictive maintenance capabilities by rendering accurate data on equipment conditions.

Some of the top commercial aircraft maintenance repair & overhaul companies include RTX Corporation, AAR CORP, GE Aviation, MTU Aero Engines AG, Hong Kong Aircraft Engineering Co, Rolls Royce plc and others.

Ultrasonic & eddy current testing – the modern NDT techniques allow for thorough inspections without damaging any parts and these techniques offer detailed insights into material conditions by finding out the flaws with high accuracy. They ensure the safety & integrity of the aircraft structures.

The emissions & noise pollutions around the airports are being reduced by the transition to electric GSE. Electric equipment also provides lower operating costs owing to decreased fuel consumption as well as maintenance needs, which aligns with broader sustainability goals in the aviation sector.

The transition to electric aviation GSE improves airport operations by enhancing reliability and precision. It reduces carbon footprints and operational expenses and helps meet stricter emissions regulations while boosting efficiency and safety standards.

These innovations improve the safety, sustainability, efficiency of aircraft maintenance. We can anticipate further enhancements in operational reliability as well as cost-effectiveness by driving the sector towards a more advanced & sustainable future since the aviation sector continues to embrace these technologies.

We use cookies to ensure you get the best experience on our website. Read more...