The global

Mechanical Power Transmission Equipment market is expected to grow from $54.58 billion in 2020 to $56.91 billion in 2022 at a Compound Annual Growth Rate of 4.3 per cent. The growth is mainly due to the companies rearranging their operations and recovering from the COVID-19 impact.

“Increasing demand for optimum performance and trouble free operation of the equipment’s in various end use industries are assisting the demand for the

mechanical power transmission equipment”, says Pritesh Shah, CEO, Power Transmission Engineers. Various types of mechanical power transmission products are available in the market such as chains, belts, couplings, pulleys, sprockets etc. These products provide various advantages which include reduced noise and vibration levels, increased output and reduced replacement and repair costs, lower energy consumption etc.

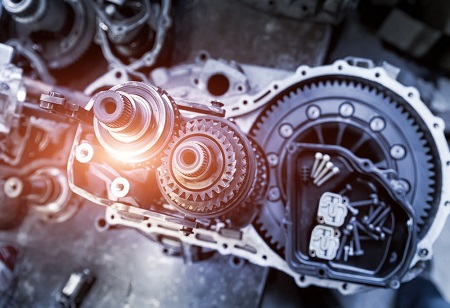

Magnetic Gears

Magnetic gears are being increasingly adopted in the mechanical power transmission equipment industry. Magnetic gears are physically contact-less, which make them enable efficiencies up to 99 per cent or more. The magnetic gears obviate the need for using any transmission oil. With the nature of contact-less operation, the gears are highly reliable and require minimal maintenance. The technology also helps prevent damage in case of a torque overload by auto-slipping, when the overload torque is removed, the gears also re-engage automatically.

Automotive Sector

One of the most common uses of mechanical power transmission equipment is seen in the automotive and transportation sector. Automotive components such as clutches provide fuel economy, quicker engine warm up, increased engine performance, and reduced noise to heavy transport vehicles such as buses and trucks. Custom bearings are designed to provide heat treatment, lubrication and part geometry to automotive rear door openings.

Machinery in Factories

In factories where industrial repairs are done, manufacture and assembly of machinery parts takes place, gearboxes and bearings provide greater reliability and increased performance to run the manufacturing system on new specifications. This improves the efficiency of industrial equipment and machinery in factories. These factors have led to greater use of mechanical power transmission equipment globally.

Mechanical Power Transmission Equipment are typically lightweight, possess a compact structure, and are suitable for short distance transmission. The rate of transmission of power is accurate, stable, and efficient. The components have a long life, thus maintaining low operating costs. The equipment can be easily installed in any system which requires transfer of mechanical energy to keep the machinery or product in motion. The components maintain the industry standards and suit most installations in systems. All these factors have increased the sales of mechanical power transmission equipment.

Industrial Applications

Power transmission products significantly affects the total cost of equipment ownership as well as the customer’s up time within an end use industry, thus they demand technical support, better availability, easier installation, reduced energy consumption, easier installation, reduced noise levels and increased service life and stability.

Industrial applications are likely to benefit from introduction of advanced mechanical power transmission systems with silent and vibration free operations developed by key stakeholders such as Hewland. Extensive know-how and multiple capabilities of mechanical power transmission system developers will continue to aid catering requirements of applications such as in heavy duty industry, material handling and water & wastewater treatment.

Electric Vehicles

Government initiatives that followed the Paris Agreement on climate change signed in 2016 are expected to increase the global demand for electric vehicles in the forecast period driving demand for mechanical power transmission equipment. For example, China plans to have at least 20 per cent of the vehicle production to be represented by electric and hybrid vehicles by 2025.

Expected increase in the production of green vehicles supported by governments’ initiatives will encourage a significant proportion of population to invest in electric vehicles and replace their existing automobiles that are running on fossil fuels, thereby driving the mechanical power transmission equipment market in the forecast period, a major supplier of metal automobile components to the automobile manufacturers.

Challenges in the Way

Many developed and developing economies are imposing restrictions on free trade which are expected to hinder the growth of the mechanical power transmission equipment market. The increase of tariffs on foreign steel especially from China by the USA government in 2018 to 25 per cent has increased the production cost of the mechanical power transmission equipment. Therefore, reduction in the world free trade is expected to hinder the mechanical power transmission equipment market due to expected increase of the production cost and tariffs.

The Future Forward

Mechanical Power Transmission Equipment is crucial to continuous and uninterrupted operation. Not only they must be analysed for supply chain support and maintainability, they should be integrated into system designs such that adequate redundancy is in place in case any components fail. The future will be all about taking the next step to predictive maintenance. The role of mechanical power transmission equipment and the importance of maintaining such equipment before a failure occurs is at the forefront, now as well as in the future.