When setting up a new workshop, initial preparations can go a long way towards improving the overall efficiency of the unit in the long run. Sure, many of the points below can be addressed later on but ensuring that they are in place from the very beginning is going to get you started on the right track, and help you build up momentum in your output. That can add up a lot when it comes to productivity measurements down the road, and it’s in your best interest to explore these options in detail.

Optimize the Physical Layout as Much as Possible

Layout optimization is a huge topic in the industrial sector right now, and for a good reason. With the advance of methodologies like Lean and Six Sigma and their heavy utilization in the sector, it’s become clear that taking the time to ensure that things are set up as optimally as possible from the beginning can play a major role on your bottom line when it comes to productivity.

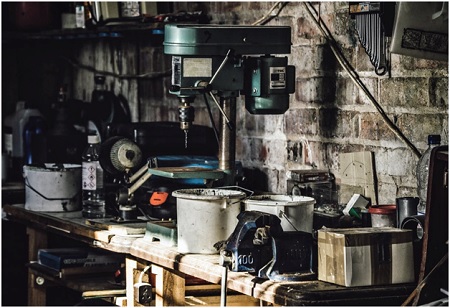

Seemingly simple and irrelevant things like minimizing walking distances, removing obstructions, and ensuring that everyone has quick access to the tools they need, are going to make all the difference.

Ensure You Have All the Right Tools in Place

You should also take your time to explore the full set of tools that you’re going to need to keep the place running and maintained. This also includes things for keeping the workshop tidy, like an industrial vacuum cleaner. Take your time to seek out the right equipment because upgrading machines of this type can be very costly later on, and you may not be able to sell your current ones at a high enough price to recoup their costs. Also, when you have the option to pick between a regular consumer-grade product and something meant specifically for industrial use, there’s probably a good reason the second option exists.

The Importance of Adequate Workplace Safety

Workplace safety is a topic that many people in the industry find annoying and try to avoid as much as possible, but in the end, it exists for a reason. You have to ensure that everyone is on the same page with regards to rules and regulations and that deviations from the norm are noticed and penalized accordingly. Nobody likes the boss who constantly tries to get them written up for not following safety procedures, but it’s for the best of everyone working under you in that facility. Invest in proper solutions like a tag lockout system and ensure that people go through refresher courses on a regular basis.

There is a lot of ground to cover at first but setting up these points in advance is going to play a major role in ensuring that your plant stays productive and safe. With time, you’ll be able to add to these areas and improve on them in various ways but getting there requires a good foundation in the first place, and that can take some time to prepare.