Modern-day technology has given manufacturers a chance to change their processes. It’s not uncommon for industries to use innovations like advanced analytics, wearables, cloud, Internet of Things (IoT), mixed-reality devices, artificial intelligence (AI) and top-of-the-range mobility to increase production. These innovations enhance productivity among first-line workers, information workers, supply chains and the manufacturing enterprise.

In any manufacturing industry, employees are the greatest asset. Therefore, creating an environment that transforms operational technology (OT) and incorporates the existing IT infrastructure is crucial for manufacturing businesses.

Product engineers, plant floor operators and field service operators are some of the employees who rely heavily on IT innovations for analytics, design and efficiency. Creating a modern manufacturing workplace will require modernising the main production areas.

This article discusses eight steps to help manufacturing businesses modernise their workplace.

1.Operations

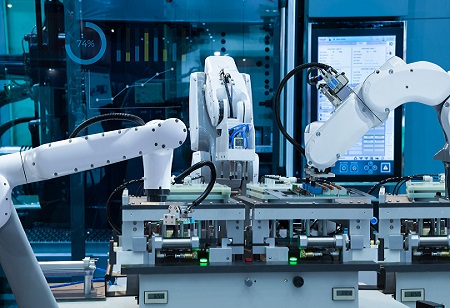

Investing in

automation tools and machinery is critical to improving efficiency on the manufacturing floor. You should automate most processes and have skilled employees overseeing the operations. Automating will get the work done faster and reduce the workforce needed.

Human-machine collaboration can help maximise team productivity and refine incident resolution. This collaboration can also make problem-solving more efficient with sophisticated knowledge management, communication and collaboration.

2.Service

Modern manufacturing relies heavily on a service-oriented approach to business. However, with mixed-reality devices, technicians can better prepare themselves before a scheduled service. These devices allow them to perform test runs to identify the problem points before starting the work order. Also, companies must provide reliable customer service for their products and meet customer promises regarding maintenance and repair needs.

Service teams should be well-trained with the latest technologies so they can address any customer issues that arise. Employees in this field must also understand the importance of proactively helping customers, such as providing advice on product features or offering solutions to improve productivity. As a result, collaboration with remote experts can help them handle the machinery servicing.

In addition, equip your technicians with the modern equipment necessary for their work. With excellent service, companies can form relationships with customers built on trust and loyalty, ensuring success in the future.

3.Material Handling

Convenient material handling systems help reduce manufacturing cycle time, minimise material handling costs and avoid production bottlenecks.

Good organization is one of the keys to efficient inventory management.

Install conveyor belt hoists and cranes for efficient material handling. Minimal columns and high ceilings don’t interfere with material movement. The material handling system will determine the workplace design since its the core of manufacturing.

4.Plant Management

Creating a more detailed work schedule, eliminating production line gaps and ensuring a seamless shift change enable your staff to improve productivity. When implementing these measures, you can gain plant insights with the data you collect.

Also, put a preventive maintenance plan for the production staff, backed up with accurate data. That way, they can anticipate any breakdowns, schedule maintenance and avoid production downtime. Don’t forget to cross-train your employees to prevent production gaps if one employee is away.

5.DataM

Data is the core of any digital operating system in a modern manufacturing workplace. Data collection enables manufacturing businesses to harvest using analytical models to aid integrative improvement.

Advanced analytics and real-time data inform the processes, people and metrics for implementing a digital operating system. Keep periodically checking and updating the data while aligning the networks for end-to-end value creation.

6.Product Engineering

With modern tools for collaboration and design, manufacturers can utilise the design potential of their product engineers. Create a centralised data analysis centre and use the data to create a product with consumer-centric designs.

Mixed reality is another tool that can help configure layouts using design concept visualisation. Instead of producing several prototypes before settling on the final design, you can install digital design equipment to determine how the different designs affect a product. This innovation reduces the time spent creating and making design alterations.

7.Cost

Cost is the primary determinant of how far you allocate to set up a modern workshop. You can use modern managerial tools like PERT or milestones to track and reduce the cost of putting up your factory.

The longer the construction takes due to delayed execution, alteration of the original design or putting the building on hold will increase the construction cost. Avoid using poor-quality materials, planning or disorganised procurement to lower costs.

8.Empower Your Staff

Technological and business trends predict that the workplace will change tremendously in the next ten years. Digital agility and upskilling will thrive over experience and tenure. That’s why you must build a workplace that empowers your employees and ensures they can adapt to the ever-changing trends.

Create platforms where employees can collaborate, share experiences and tap into digital advancements based on the current industry standards. Tools like Office graph enhance modern work styles and collaboration, empowering first-line workers.

Conclusion

There has been a growing need for industries to implement digital operating systems and Industry 4.0 to create modern innovative, insightful and inclusive workplaces. A modern manufacturing workplace gives you a competitive advantage while building a profitable business for the future.

Make sure you use digital technologies to improve your production process, quality and customer engagement. Several digital advancements can assist in setting up a modern industry and help you track your production. Your production strategy should leverage talent, technology and leadership for sustainable production.