The advent of lasers has brought a revolution in global technology, owing to their multi-dimensional characteristic nature. The very fact that uncontrolled lasers, on one hand, cause irreversible damage to the eyes but if rightly controlled, are also capable of performing critical eye surgeries reveals the ability of lasers to operate in a broad range.

Over the years, the true potential of lasers has been realized through their expanding capabilities from high-end lab experiments such as optical tweezers and laser cooling of atoms to day-to-day operations viz., laser barcode scanners and laser engravings. Lasers are used in many applications from research and defence to medical instruments.

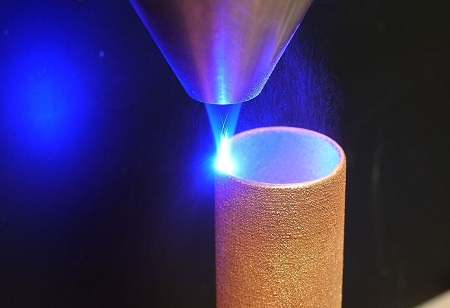

In the field of medicine, lasers are used to treat specific areas of tissues and complete cosmetic surgeries. In the manufacturing industry, lasers are used to cut through materials with high precision and are also used in additive manufacturing procedures to improve precision in 3D printing. Even in military operations, laser-based warfare is the advanced mode of attack adopted.

Lasers unlike conventional light, possess high intensity, coherence, directionality and monochromaticity. They don’t diverge with respect to the distance travelled, whereas conventional sources do. Thereby, the maximum power of the laser can be transferred over large distances. Hence, a large amount of energy is concentrated on the spot size and achieves high power densities.

As lasers are operated by humans, there are possibilities that reflections can damage vision permanently. Unintentional heat can vaporize skin tissue or cause retina lesions and skin burns. Therefore, reducing the laser intensity that enters the eye is vital. The severity of lasers can be imagined as a man can see a 100W tungsten bulb glow with little discomfort; however, laser light with <1W of power can damage vision without intimation.

As laser technology is growing and has adverse effects on humans, there is a high demand for laser safety equipment.

Lasers are classified into four types, 2M, 3R, 3B and 4 based on their power intensity. Laser protective eyewear and solutions are in high demand in the field of science and technological advancement. In conventional applications, three types of laser goggles are in use — polycarbonate filters, absorption glass, and dielectric filters and coatings. One form of laser protection is through laser safety coatings or filters done through thin film depositions. The filter deposited on the goggles blocks specific laser wavelengths and transmits the visible region of the electromagnetic spectrum through it (VLT-visible light transmission). Optical Density (OD) is the attenuation factor of a filter at a specific wavelength. For better understanding, 100%, 10%, 1%, 0.1% & 0.0001% in the transmission scale equals 0, 1, 2, 3 and 6 in OD scales respectively, commonly used for denotation purposes.

Polycarbonate filters work from low to mid-power density lasers and absorption glass reduces VLT. The dielectric filter or coating has an advantage over these two solutions by blocking specific laser wavelengths and transmitting visible light through them in the range from mid to high power lasers. These filters can be designed as per the power and frequency of the laser used. These filters go through stringent quality control tests due to their direct relation to eye safety. The spectroscopic analysis gives the blocking ability of filters at wavelengths in the scale of OD and VLT%.

Aerospace, automotive, electronics and semiconductors, medical, food and textile, construction, utility and other industries use different types of lasers such as CO2 lasers, fiber lasers, solid-state lasers, etc., for versatile applications like marking, micro-materials, and macro-materials with a wide range of laser power intensity. Global manufacturers of laser safety goggles are KCWW, Honeywell International Inc., 3M, Uvex group, W.W. Grainger, Inc., Phillips Safety products, Thorlabs, Kentek Corp., Laser safety Industries, Global laser Ltd., VS eyewear, Univet, Trotec Laser GmbH, NoIR Laser Co., LLC, Laservision, Cole-Parmer Instrument Co., LLC, and Laser components.

With a compound annual growth rate of 12.4%, the Global industrial lasers market size is projected to rise from USD 5.66 billion to 14.52 billion within the period 2018 to 2026. The product has had a large demand in recent years, as the market has exponentially grown in all fields. High throughput production facilities are required to support the increase in demand for laser goggles.

In the view of the future scope of laser applications, lasers will be a key contributor in many advanced fields including sensors, digitization, artificial intelligence to data encryption in quantum technology to name a few. To start with, ultra-short high intensity femtosecond laser pulses are the future of biomedical applications that will help both in imaging and conducting intricate specific area targeted surgeries.

With regards to electric vehicle (EV) manufacturing, laser welding makes it possible to achieve narrow and high-speed welding at a lower heat which is crucial in EV batteries. Whereas self-driven cars employ laser-based scanning to map the targeted area in which the laser acts as the eye of the car. In addition, the progress in shrinkage in the size of semiconductor lasers, diode lasers, and several others, widens the possibility to employ them in various intricate applications. In conclusion, with the explosion in the innovation of laser technology, to be able to work with lasers and take advantage, an understanding of laser safety is extremely important in the first place.

(Special thanks to Dr. Arindam Sarker, CTO of ASM-HHV Engineering Pvt. Ltd., for his input and advice)

We use cookies to ensure you get the best experience on our website. Read more...